Engineering programs running in major universities of the world found it difficult to perform

experiments online during the Covid-19 outbreak. The theory portion of most programs was

conducted online [1]. However, for lab sessions, no alternative was found. The students were

asked to physically appear in labs in smaller groups and in different time slots in order to

reduce the spread of infection. To administer the lab component of engineering courses

online, it was anticipated that a new integrated environment will be required for remote

experimentation. The goal of this endeavor is to create a digital twin of each lab experiment

using online apps, augmented and virtual reality (AR/VR), interactive movies, and problem-solving sessions to encourage critical thinking [2].

The digital 3D representation of a machine in such virtual engineering labs (VEL) accurately

depicts the behavior of the machine. A lab engineer or instructor might oversee the students’

real-time engagement with the virtual plant model or robotic arm models and provide rapid

feedback [3]. The hardest part of the remote lab scenario is assessing and improving a

student’s psychomotor abilities.

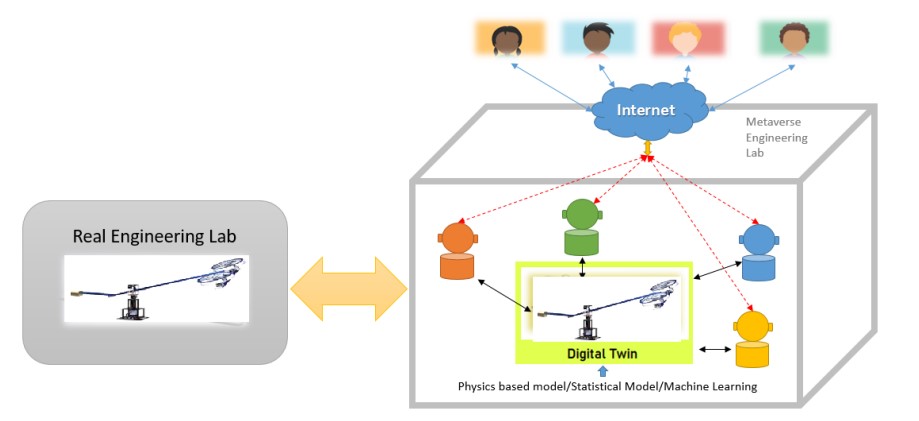

Figure 1 3DOF helicopter lab metaverse in Control Engineering Course

Figure 1 3DOF helicopter lab metaverse in Control Engineering Course

Since lab work is regarded as an essential component of engineering education, it is important

to take into account the possibility of an online lab based on digital twin and metaverse

immersion that can deliver the laboratory experience exclusively online using digital replicas

of electrical machines, network analysis, smart grid, control systems, fluid mechanics,

thermodynamics, flight dynamics, and turbo machinery laboratory experiments.

For experiments utilizing expensive, high-powered, or delicate equipment, the 3D-based

virtual learning environment in the metaverse for teaching engineering courses can offer an

open and secure learning environment. Working without actually handling any physically

dangerous electrical components is an opportunity. Artificial intelligence (AI) directed

laboratory tasks may be completed without ever being present in a real scenario by

implementing immersive metaverse based engineering laboratories [4]. The cost of building

a lab, which need several comparable test benches for group projects, will be greatly reduced

as a result.

In Fig. 1, a three degree of freedom (DOF) helicopter experiment, which is regarded as one of

the key experiments in realizing a closed loop feedback control system, is shown operating in

a VEL combining a digital twin and metaverse. Such laboratories give educators the

opportunity to design simulated experiences for a greater number of online students while

giving students the opportunity to learn from virtual simulated systems in an interactive, safe,

but entertaining manner. Despite these advantages, VELs are not yet developed enough to

address some of the key engineering skills needed for learning in outcome-based education

(OBE), such as psychomotor skills. This is mainly because the haptic devices needed to

simulate touch in remote labs have technological limitations and are expensive.

The first step is to design a closed-loop simulation in Simulink to improve the stability and

performance of the open loop dynamics. Students then apply this controller to the digital twin

by interacting in the VR environment. Through remote or virtual access to the helicopter, they

can verify their simulation designs on the lab equipment by using Simulink Desktop RealTime™. This is achieved through executing the Simulink controller models in real time on a PC

connected to the real test bench as hardware in loop (HIL) simulation. Thus, by integrating

the virtual Lab framework into the present engineering curriculum, students are able to

connect the MATLAB/Simulink models directly to VR devices using automatic code

generation. Using a Microsoft® HoloLens headset, they can further interact with the 3D

helicopter in the augmented reality environment, where it is possible to see the physical

system beside the digital twin, with the provision to adjust controller gains directly in the

virtual environment [3].

In a nutshell, the metaverse augmented lab provides students with a synchronous 3D

environment in which to engage with one another and the digital twin of the experimental

test bench in the distant lab. The Internet of Things (IoT) and a physical plant combined with

the virtual metaverse make up the cyber-physical system that the virtual test-bench refreshes

with status information via communication network providing an effective setup for lab

experiments.

References:

[1] Khan, Z. H., & Abid, M. I. (2021). Distance learning in engineering education: Challenges and

opportunities during COVID-19 pandemic crisis in Pakistan. The International Journal of Electrical

Engineering & Education, 0020720920988493.

[2] Khan, Z. H., & Abid, M. I. (2017). Role of laboratory setup in project-based learning of freshmen

electrical engineering in Pakistan. International Journal of Electrical Engineering Education, 54(2), 150-

163.

[3] Alsaleh, S., Tepljakov, A., Köse, A., Belikov, J., & Petlenkov, E. (2022). ReImagine lab: Bridging the

gap between hands-on, virtual and remote control engineering laboratories using digital twins and

extended reality. Ieee Access, 10, 89924-89943.

[4] De Felice, F., Petrillo, A., Iovine, G., Salzano, C., & Baffo, I. (2023). How Does the Metaverse Shape

Education? A Systematic Literature Review. Applied Sciences, 13(9), 5682.